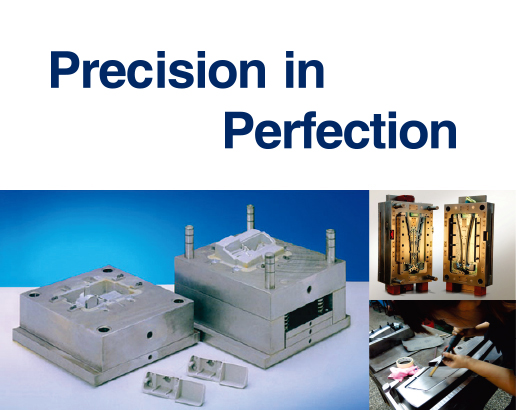

RAPID TOOLING

In order to meet the requirement of function prototype with original material for various testing before production, ABLE use metal epoxy and aluminum alloy as the mold insert with our in-house various standard mold base system to make high quality injection at a reasonable short time & tighten schedule.

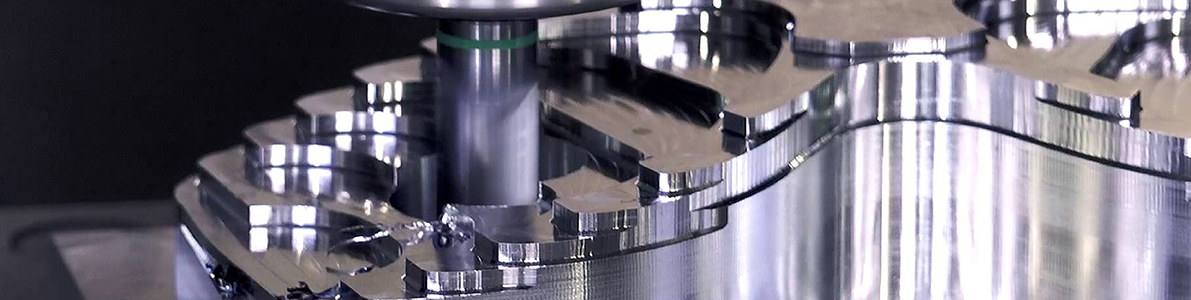

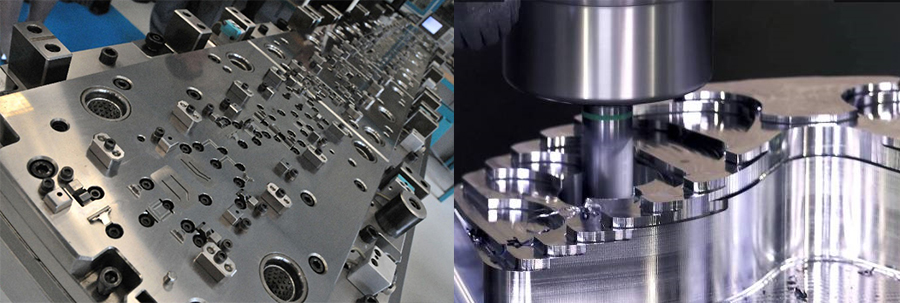

PRODUCTION TOOLING

ABLE start with rapid tooling and accumulate more unit than 20 years experience at tooling fabrication, we already developed our tooling team for export tooling and complicated structure tooling, for example hot runner system, pneumatic control, hydraulic control, stack mold and etc.,

We assist our clients with specifying materials, surface finishes, slip angles, split lines, injector positions and much more. Based on 3D CAD models developed by our engineering team or sent to us by our clients, we develop the tools to exact specifications, be it for marine or medical applications. Our clients can order tools for use in their own production or simply use our production set-up. Our tooling experts offer guidance through the complete process from the first idea to final delivery.

Now ABLE is one of approval tooling manufacturing enterprise at automotive industry.